Axial Deviation Tester sourcing|axial misalignment in testing : services Alignment of the axial test machine load-train is critical to many types of mechanical testing of materials including tension, compression and fatigue [1-3]. This document describes a method for verifying the machine alignment by means of measuring the bending on the surface of a strain . WEBMarie Faldonado 57 Episodes 2020. Grace Kaufman. Kate Burns 69 Episodes 2020. Kali Rocha. 66 Episodes 2020. Hala Finley. Emme Burns 69 Episodes 2020. Matthew McCann. Teddy Burns 69 Episodes 2020.

{plog:ftitle_list}

Tv Arapuan. Veja Mais. TV Allegro. TV Explosão Fm. TV OMINDARÉ . Tv Princesa do Vale. Previous. Next. RedeiTV - todos os direitos reservados .

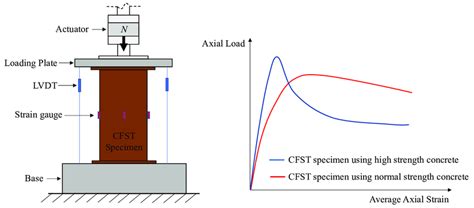

Alignment of the axial test machine load-train is critical to many types of mechanical testing of materials including tension, compression and fatigue [1-3]. This document describes a method for verifying the machine alignment by means of measuring the bending on the surface of a strain .A simple, structured evaluation in testXpert enables a ZwickRoell service technician to identify errors in the test axis on the basis of characteristic measurement results. If necessary, measures can be taken using components . Methodology. Axis Deviation Tester Market Outlook. The global Axis Deviation Tester market size was estimated at USD 450 million in 2023 and is projected to reach USD .Apply simultaneous axial and torsional loads and displacements to a wide array of specimens. This highly versatile test system is capable of everything from static testing to multiaxial .

Our alignment transducers meet the requirements of ASTM E1012, Verification of Test Frame and Specimen Alignment Under Tensile and Compressive Axial Force Application.Under ideal conditions, axial measurements should show very little vibration as most forces are generated perpendicular to the shaft. However, misalignment and bent shaft problems do .

The Instron ® planar biaxial cruciform testing systems feature high-stiffness, precision-aligned annular load frames combined with 4 advanced actuators mounted in-plane and perpendicular .ZwickRoell offers various solutions for biaxial and triaxial materials testing. Materials testing machines with torsion drive enable fast, precise biaxial testing (tensile or compression combined with torsion) of materials or components up . Evaluation Testing That Approximates Operating Conditions of Materials and Parts - Loading methods similar to actual usage - Allows simultaneous application of axial and . One established deviation model for the axial turbine is proposed by Carta and Hughes [25] based on their well-used model for compressor cascade, . Then, the apparent discrepancy in turbine performance exists with coupling the loss and deviation models compared with the test data. Therefore, the method of optimizing the empirical coefficients .

This paper investigates the influence of additive manufacturing (AM) surface roughness on the aerodynamic performance of axial compressor blades. Though the AM offers advantages such as complex geometry fabrication and .

axial strain alignment testing

Tension test, alternatively referred to as tensile testing or uniaxial tension test, is one of the most commonly used tests to determine important material parameters such as Young’s modulus, yield strength, ultimate . The Ilizarov bone transport technique is widely recognised as an effective method for treating large segment bone defects in clinical practice. However, axial deviation is a common complication in the treatment of tibial large segment bone defects, which can have a serious impact on the clinical efficacy of bone transport. Our study aims to construct and validate a .3.3.2 Test procedure. The test is quite simple and the interpretation is fairly straightforward. A cylindrical core of at least 54 mm in diameter (NX core) and length/ diameter ratio of 2.0–3.0 (ISRM suggests 2.5–3.0 and ASTM D 7012 suggests 2.0–2.5) is subjected to an axial load that is increased to failure. In order to improve the efficiency of axial load transfer, a great deal of theoretical and experimental works focusing on drill-strings' drag force have been carried out (Mirhajmohammadabadi et al., 2010).In the conventional approach (Johancsik et al., 1984), drill-strings were considered as a cable under tension, the so-called soft-string model, which can .

Verticality axis deviation tester/verticality axis deviation detector GB/T 8452-2008 YBB00332002-2015, You can get more details about Verticality axis deviation tester/verticality axis deviation detector GB/T 8452-2008 YBB00332002-2015 from mobile site on Alibaba.com . How sourcing works. Membership program. Trade services Trade Assurance .

The figure shows the limits for the diagnosis of axial deviation left (-30 °, -90 °) and of right axial deviation (+ 90 °, + 150 °). The path (ecg), therefore, must be searched for the highest QRS complex in the various derivations to understand where the direction of the cardiac vector falls.

The deviation angle was calculated using Lieblein [28] 's models for the minimum loss deviation angle (δ min) and deviation due to the incidence angle (δ i) and Hearsey [29] 's deviation angle due to the axial velocity ratio (δ v a). Since enthalpy is a function of temperature, the outlet temperature that satisfies the enthalpy was .

axial misalignment in testing

axial misalignment

standard deviation measurement and consequently should be considered as part of the noise source. Although standard deviation is the most straightforward way of measuring noise in an image and correlates fairly well with visual observation, it also has many limitations. As an illustration, Fig. 5.33 shows three images with different types of noise. We provide global averages and standard deviations for ocular biometry—axial length (AL), corneal radius of curvature (CR), anterior chamber depth (ACD), lens thickness (LT), white to white (WTW .

Specifications for the MICROSEMI 53100A Phase Noise and Allan Deviation Tester Include: Frequency Range: 1 to 200 MHz: Offset Frequency Range: 0.001 Hz to 1 MHz: Allan Deviation : . Your testing is complicated enough, we want to make sourcing test equipment the easy part. Dedicated Customer Service

In the test studies of transonic compressor stages, researchers discover a sudden increase in the deviation angle compared with subsonic stages, 8 and propose the following deviation models. Swan 9 considered the influences of inlet Mach number and equivalent diffusion factor, and modeled the deviation model based on linear functions. Fei and Ji 10 .

Positioning for PA axial - Seat patient at end of table, with wrist and hand on IR, palm down, and shoulder, elbow, and wrist on same horizontal plane - Palm down and hand and wrist aligned with center of long axis of portion of IR being exposed, with scaphoid center to CR - Without moving forearm, evert hand as far as patient can tolerateprimarily from single-stage compressor test installations. The parameters that describe blade-element flow (total-pressure loss, incidence angle, and deviation angle) are discussed with reference to the many variables affecting these parameters. The blade-element data axe correlated over a fairly wide range of inlet Mach number and cascade .When the axis moves further and is more negative than −30° it is called marked left axis deviation (MLAD) and, on inspection of the tracing, . change in bodily posture) to test the stability of the axis. If it varies, the serious pathologic nature of the axis deviation is less likely. The numeral values for such variation, however, need .

the detection accuracy of the X-axial rotation deviation is 0.0654 with the background changing during the probe movement. The repeatability of the test procedure is ±0.16%, Perturbations in the strain fields represented by a standard deviation of 0.1% in axial strain ε x and 0.5% in maximum shear strain γ 12 can be seen with having the largest values, largest strain gradients, resp., at the top, close to the grips. Shear strain concentrations in the corner of the coupon specimen are more obvious close to . Abstract The paper describes an improved streamline curvature approach (SLC) to the flow field analysis and performance prediction of transonic axial compressors. The previous research concerning the incidence angle, deviation angle, and total pressure loss models is discussed. Many semi-empirical correlations and curve fits were based on two .

The axial deviation of an optically trapped particle in the trapping force calibration using the drag force method is experimentally observed and theoretically analyzed with the ray optics approximation. It is concluded that the particle deviates from the original trap center not only laterally but also axially when the particle endures an .

The analysis of aero-engine bearings is crucial for the advancement of aero-bearing technology and the improvement of the reliability of aero-engines. During a test of an aero-engine spindle bearing, an abnormal noise was detected. Upon investigation of the damaged bearing, a failure analysis was conducted through various methods including macroscopic and . During the reliability performance test, the axial thrust balancing device of GFQ150-700 was overloaded and damaged due to an unsuitable designed value of axial thrust. The designed hydraulic axial thrust with the actual value is compared in this article, and the reason for axial thrust deviation is discussed.

driving final test hard practice nj on signs

WeiMin Industrial, FORWARD SURGE TESTER (For SMD、AXIAL Package Type), DIODE TESTER, SMD、AXIAL Package Type, Wafer Test Equipment, Semiconductor Test System, Test Equipment for LED Devices, . Four-wire measurement and contact resistance in case of deviation. Manual test or conjunction with automatic machine. Special Functions.

Friend, I would recommend you make a test to both probes with a TK-3 in order to get the relation between distance and Volts. Normally the relation between distance/volts is 200mV/mils, this depending of target material and probe used, I mean if you have a axial displacement of 5 mils the voltage produced will be 1 volts.Based on the test results, the axial vibration displacement, velocity and acceleration of the tool were obtained from 0 to 2 s, shown in Fig. 15 a. When the pump displacement is set to 15 L/s, the maximum axial vibration displacement generated by the tool is 6–8 mm, the velocity is 0.1–0.15 m/s, and the acceleration is 8–10 m/s 2. Axial dispersion number (D/uL) and mean residence time (τ) can be calculated by fitting the analytical solution to axial dispersion model to experimental F-curve transition data. Numerical modeling tools can be used to quantify the dampening of disturbances (e.g., mass flow oscillations) by axial dispersion and reactor configuration.loss and deviation models will be developed in the predic-tion framework for updating the empirical coefficients with the evolution of the turbine design concept based on minimiz-ing the deviation between prediction and test performance. 2. Turbine performance prediction framework The axial turbine performance prediction framework consists

driving practice test harder to pass than real test

webO Portal Zacarias, um renomado site de humor brasileiro, desempenhou um papel crucial na propagação do meme “olha a carinha dele ai”. Ao captar a essência engraçada e viral do vídeo original, o portal não só ampliou o alcance do meme, como também explorou sua maleabilidade criativa, gerando inúmeras variações que mantiveram a chama do humor .

Axial Deviation Tester sourcing|axial misalignment in testing